The PLUS transceiver provides a communication interface which is also applicable for further applications where high reliability and functional safety are key.

Pls. contact us in such a case under info@plc-tec.ch

Less wires → Less weight → Less emissions → Cleaner aircraft

Besides the lower procurement costs for less wires, as jet fuel accounts for about 30% of airline costs, a reduction in weight will lead to a significant fuel cost savings over time. E.g., a 100 kg weight reduction will lead for an A320 aircraft to yearly fuel cost savings in the range of 20’000 $ and over a 25 year lifetime of the aircraft to 0.5 Mio $.

A means is required in order to reduce the overall amount and therefore weight and costs of wiring in the aircraft.

= Lower Costs

= Less Emissions

= Faster Aircraft Manufacturing

= Less Maintenance

Power Line Communications

An innovative solution reducing the number of wires in the aircraft is the use of Power Line Communications (PLC). With PLC, data is transmitted over the existing aircraft Power Distribution Network. The general concept for PLC in an aircraft is shown on the right side and consists of the following main points:

• Data network completely removed

• Single connector for power + data

• Data transmission independent of the underlying power signal

• Communications protocol designed for transmission in harsh environments

PLC provides the following benefits

• Lowers operational costs and emissions through a reduction in aircraft wiring weight

• Lowers the required wiring design and routing effort due to the reduced wiring complexity

• Reduces life-cycle costs of airplane wiring as less maintenance is required.

The PLUS AVIONICS data bus is a PLC protocol and technology platform specifically targeting safety-critical, real-time systems in aerospace applications. It has been designed around:

• A proven standard from other industries for the physical layer (IEEE 1901)

• A proven avionics standard for bus arbitration (ARINC 629)

• Custom optimizations and additional protocol layers

One of the main design goals has been to use the available bandwidth from the broadband transmission in order to optimize the data availability and integrity rather than simply increasing the data rate.

The PLUS AVIONICS protocol works on top of any power distribution network without requiring any modifications to the existing wiring. The signal is modulated independently of the underlying power signal. PLUS AVIONICS fullfils the main challenges for the use of PLC within the aircraft:

• Achieving availability and integrity requirements by providing robust communications

• Fulfilling Electromagnetic Compatibility (EMC) requirements for both emissions and susceptibility

For aeronautics applications Diehl Aviation and plc-tec AG have entered into an exclusive cooperation for the further development, certification and industrialization of PLUS AVIONICS. This agreement opens the door for Diehl Aviation to use the PLUS technology for the transmission of data over power distribution networks to be integrated into their aerospace products. This also enables customers and partners of Diehl Aviation to utilize the benefits of PLC AVIONICS for their own products and solutions.

Diehl Aerospace together with partner HSLU have won the 2017 Crystal Cabin Award for Cabin Systems for “Power Line Communication (PLC) for Aircraft.”

Diehl Aerospace showcased PLUS AVIONICS as an enabler for the smart cabin of the future at the International Aerospace Exhibition (ILA) Berlin (June 22 to 26, 2022).

The Competence Center Intelligent Sensors and Networks is the major research partner of the plc-tec, e.g. in cooperations in several EC and LUFO (German aerospace research program) projects.

Project Description: Demonstrate a TRL of 4 for PLC and Power over Data (PoD) technology using the Cabin Lighting and Communication System (PLC), the Cockpit Display System (PoD) and optimizing the architecture of the system for power and data transmission in terms of topologies, EMC, security, integrity of data, etc. Members of plc-tec defined an optimized solution for arc fault detection using additional sensing components within the PLC coupling module. This solution has since been patented.

Project Description: Consolidate and extend the efforts of several independent projects by improving the IMA2G Distributed Platform Solution (modular data architecture). The application of PLC was one of two new technologies that was additionally evaluated within the project. Members of plc-tec were responsible for providing the PLC technology within the project (PLUS technology). PLUS AVIONICS was used to enable communications for the Ventilation Control System (VCS). Control between the Remote Power Controller (RPC from Diehl Aerospace) and the fans of the VCS (from Nord Micro) was realized with PLUS AVIONICS. The PLUS AVIONICS technology was seen as a major success story by both the project partners and the EC.

Project description: Design, develop, manufacture and validate the advanced electrical power distribution system (EPDS) based on Multifunctional Power Network with Electrical Switching. This will be a key component in the creation and demonstration of the Multifunctional Fuselage demonstrator being developed within Clean Sky 2 LPA IADP platform 2. The technical areas of work covered advanced architectures for the Electric Power Systems (EPS) including Power Electronic Switches based on Solid-State Devices, onboard communication networks and Power Line Communication (PLC). plc-tec’s research partner HSLU was responsible as a work package leader for providing the PLC (PLUS AVIONICS) technology.

Project Description: More Electric and Connected Aircraft (MECA) is one of the most promising enablers to reach Flightpath 2050. But MECA asks for more electrical systems, which exchange more data that can be safety critical, and consume more electrical power leading to higher thermal dissipation. This leads to complexity, weight penalty and increased exposure to intended (cybersecurity) and unintended (Electro Magnetic Compatibility) interference. Overcoming these barriers requires an interdisciplinary cooperation and, in this context, the ADENEAS project emerged, aiming at paving the way for a safe, light, self-configuring, autonomous and modular power and data distribution network that is scalable to all aircraft sizes. ADENEAS stands for Advanced Data and power Electrical NEtwork Architectures and Systems. It is a H2020 project, which started in February 2021 and will run for 36 months. It has a budget of more than 4 M€ and a consortium of 9 partners led by Fokker Elmo. plc-tec leads work package 3 which aims to develop a scalable data bus solution for communicating data over the aircraft power distribution network using Power Line Communication (PLUS AVIONICS) technology.

Project Description: plc-tec partners with FHNW Institute of Automation in this project supported by the HIGHTECHZENTRUM AARGAU and co-funded by the FORSCHUNGSFONDS AARGAU. The goal of this project was to optimize the analog circuits of the PLUS modem prototype for Electromagnetic Compatibility (EMC) while investigating new circuits for reducing the size, weight and costs of the modem. As a result of the use of nanocrystalline materials, a significantly increased interference immunity was achieved for the inductive coupler principle and, in addition, a significantly smaller inductive coupler circuit is made possible.

Power Line Communication for Safety Critical Applications (EC ASHLEY Project 2017)

Health Monitoring System for Aircraft Electric Drives

Reliable train communications backbone for the future Full Digital Freight Train

Transport is responsible for 25% of the European Union’s greenhouse gas emissions, while rail transport accounts for only 0.4%. The goal is to massively shift road transport, which currently accounts for 75% of inland freight traffic, to rail.

The freight train has hardly changed in recent decades. The high proportion of manual processes and the low level of automation lead to competitive disadvantages such as high shunting costs (last mile) and long unproductive downtimes. In addition, the transport structure is changing as a result of deindustrialization: smaller units to be transported have to travel over shorter transport distances.

For the necessary leaps in innovation through automation, digitization and intelligent train applications, a continuous power supply and data communication in freight trains is a prerequisite. The coupling between the wagons is a crucial component here.

The key element for the future Full Digital Freight Train is therefore the Digital Automatic Coupler (DAC), which automatically couples not only the mechanics and the air brake pipes, but also the power lines and communication system, thus enabling the required power and data supply across the entire freight train.

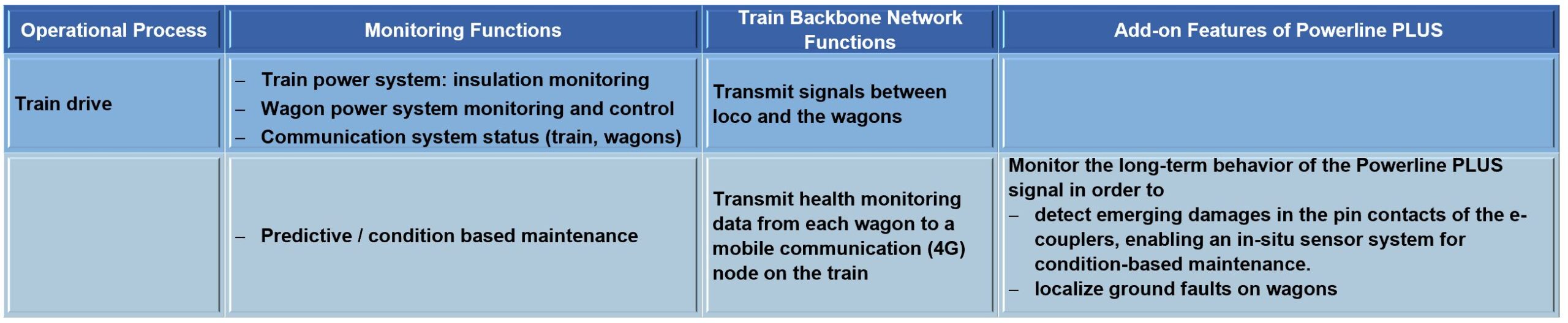

The most important requirement for the DAC is its reliability. It must operate reliably in the harsh operating environment of freight trains, where, e.g., wagons collide at up to 12 kmph during coupling. In particular, the e-couplers in the DAC with the electrical contacts for power and data are subjected to massive stress. The key to achieving maximum reliability is therefore to reduce the number of electrical contacts to be coupled to a minimum.

To achieve this goal, a PLC solution offers a unique advantage as the electrical power contacts can be used also for data communication.

PLC is not new to freight train applications. It has been successfully employed for more than 20 years in North American freight trains for the control of the braking system.

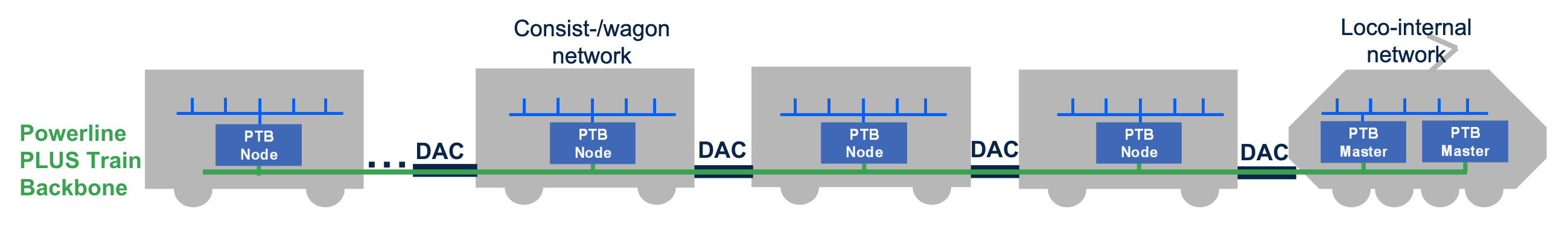

The Power Line PLUS Train Backbone (PTB) based on plc-tec’s PLUS technology has been designed as a train backbone network in which PLC is used for data communication via the power distribution line on the future Full Digital Freight Train.

As PTB transmits data over the train power line and the respective electric power pin contacts in the e-coupler of the DAC there is no need for any additional data pin contacts in the DAC. This represents a major advantage regarding the reliability of the data communication because fewer pin contacts in the DAC means lower susceptibility to faults, lower maintenance costs and longer life cycle.

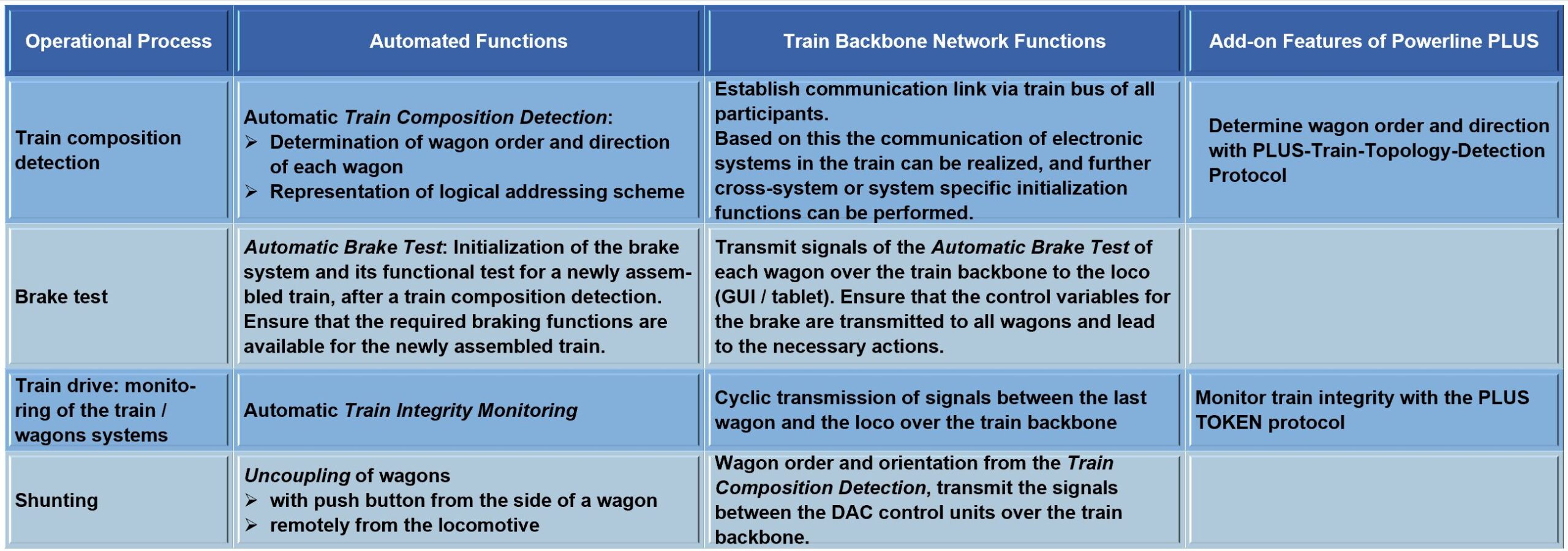

PTB has been designed to incorporate ALL signals of the automated and digitalized functions of the future Full Digital Freight Train, including control and monitoring signals of the Train Composition Detection, Automatic Brake Test, Train Integrity Monitoring, Remote Uncoupling of wagons from the locomotive, train energy system, electro-pneumatic ep brake system, multiple traction system, etc.

Further montoring functions which are relevant for the operation of the FDFT:

New protocols for PTB have been designed on top of the PLUS technology taking these requirements into consideration.

• The PLUS-TOKEN protocol enables deterministic access control using a master-slave based token passing protocol. It is optimized for the linear train topology and provides low latency and high reliability with no single point of failure.

• PTB provides a Quality of Service (QoS)-based solution for safety-critical multiplexing to enable the coexistence of safety-critical and non-critical applications.

• The PLUS Train Topology Discovery (PLUS-TTD) protocol is used to automatically detect the order and orientation of all the wagons in the train for the train inauguration.

Under development: Further innovative features of PTB

• In-situ health monitoring of the state of the e-couplers in the train set with a suitable sensor system and signal processing based on it, which detects emerging damage in a timely and reliable manner.

• In-situ ground fault localization on wagons

• European DAC Delivery Program (EDDP) selected PTB as one of two short listed technology candidates for the train backbone.

• DAC4EU tests: PTB has so far achieved the best results and reliably recorded train integrity and wagon order

• First public demonstration of an important automated train function for the Full Digital Freight Train – the Remote Uncoupling of Wagons, controlled over the PTB and with Voith’s DAC5 system, demonstrated by plc-tec’s R&D partner HSLU and SBB Cargo.

SBB Cargo, the rail freight subsidiary of Swiss Federal Railways SBB, and plc-tec cooperate since 2018 in the area of the Full Digital Freight Train.

HSLU and plc-tec participated in the expert groups in workpackage WP1, e.g. in the assessment of the communication technologies for the train backbone and of the power distribution system.

Result: PTB is one of two short listed technology candidates for the train backbone.

HSLU and plc-tec participate in the DAC4EU project where the PTB technology as one of the communication technologies for the train backbone is currently tested. PTB modem prototypes have been integrated into the wagons.

Result (officially published on November 30, 2022, link to the detailed results): PTB is the most reliable communication technology for the DAC.

FP5-TRANS4M-R’s overall goal is to establish rail freight as the backbone of a low-emission, resilient European logistics chain which fulfills end-user requirements to full satisfaction. Two technological clusters, ‘Full Digital Freight Train Operation (FDFTO)’ and ‘Seamless Freight Operation’, will develop, validate and demonstrate FP5-TRANS4M-R technologies, in line with an integrated cross-sector systemic approach. Integrating Digital Automatic Coupler (DAC) enabled solutions with software defined systems and digital rail services will ensure increased capacity, higher throughput and swifter transportation. It will strengthen the cross-border coordination and cooperation between rail infrastructure managers and deliver optimised rail network management. FP5-TRANS4M-R’s seamless, integrated, interoperable, validated and EU-wide authorised solutions aim to achieve a single EU rail freight technology framework with strictly managed interfaces for effective system integration and seamless operation across borders, actors and modes. These objectives provide the foundations, framework and motivation behind the project which will have significant impact on the EU transport and logistics sector.

FP5-TRANS4M-R brings together 71 partners from across the rail sector including end-users, industrial partners, railway undertakings, operators, wagon keepers, SMEs and academia. The project will deliver on the rail freight sector’s commitment to increasing the modal split share to 50% by 2030, revoking the causality between economic growth in Europe and pollution and having a positive impact on European citizens’ quality of life.

plc-tec contributes to the WP18 SBB DEMO: DAC Powerline Plus Communication Solution.

plc-tec, HSLU and SBB Cargo test PTB as train backbone for automated train functions like train composition detection, automatic brake test, train integrity monitoring, uncoupling from the locomotive, etc. The focus is on testing the reliability of the automated train functions in the tough operational processes with harsh environmental conditions, etc. A DAC+ test train is assembled, with a number of different measuring devices, and stand-still, shunting and drive tests will be performed. Further project partners are VOITH and PJ Messtechnik. The project is co-funded by the Swiss Federal Office of Transport.

PLC Train Backbone (PTB) Demo with VOITH and HVLE (October 2021)

DAC+ tests have started in Switzerland (March 2023).

The DAC+ Train – Test System (July 2023)

The DAC+ Train – Test results of the Automated Train Functions (August 2023)

Hightech Zentrum Aargau (HTZ) 10th anniversary event (August 2023)

Hightech Zentrum Aargau (HTZ) 10th anniversary event including the full presentation of Prof. Dr. Jürgen Wassner, CDO of plc-tec. (August 2023)

Ethernet networks are used today for networking passenger information devices on trains. However, these are expensive and require a large amount of cable with corresponding space requirements and weight. This can be improved by using Power Line Communication (PLC) to transmit data via power supply cables.

There is continuous price pressure in the rail industry. A further reduction in costs in on-board passenger information seems only possible with new concepts.

Passenger Information Systems (PIS) in today’s trains consist, among other things, of audio components (amplifiers, emergency call stations) and an increasing number of displays in various technologies (TFT, LED, OLED, …). Today, these devices are typically interconnected via a train-consist internal Ethernet network (Figure 1). A modern train has several hundred PIS devices. The length of the required network cables can be over 50 km per consist. Together with the required Ethernet switches, this is a significant cost, space, maintenance and increasingly weight factor.

With data transmission using Power Line Communication via existing power supply cables to the individual PIS devices within a train consist, a considerable part of the Ethernet network can be eliminated, which would significantly reduce costs and cable space.

With plc-tec’s PLC Consist Network (PLUS-PCN) solution, based on the Power Line data bUS technology and developed in close cooperation with the research partner HSLU and the leading PIS vendor ANNAX-Wabtec, the existing switch Ethernet-based PIS network can be completely removed for intra-consist communication. The Ethernet-based backbone network remains, but interfaces directly to the PLC modems via the power supply, eliminating the need for Ethernet switches. This provides a cost-effective solution using the existing power distribution cabling.

This architecture involves the use of two PLUS-PCN Concentrators per consist (one at each end) connected to the Ethernet backbone network. This provides equivalent redundancy to an Ethernet-based solution. A PLUS-PCN modem including coupler and power supply unit for the 36 V DC train PDN is integrated in each application terminal. The power supply and coupler versions meet all relevant relevant railroad standards for electronic devices and EMC. Suitable interfaces to the existing application devices have been developed, which support the VLAN/IP address support.

For a field test, a prototype system consisting of four PLUS-PCN prototypes was integrated into a passenger train (MUTZ Stadler) of the Swiss railway operator BLS AG. A PLUS-PCN concentrator was connected to an existing PIS switch. One PLUS-PCN modem each was installed on a TFT display, a side indicator and an audio amplifier.

The applications that run on PLUS-PCN are audio announcements, TFT display updates, and page display updates.

The PLUS-PCN prototype system has been running in normal train operation since January 2019, in temperatures below 0 °C in winter and above 40 °C in summer. Through a combination of remote monitoring of the passenger information system in conjunction with the connection to the PLUS-PCN modem prototypes, the system is constantly monitored.

Tests have shown that the total throughput of the new PLUS-PCN network is approximately 20 Mbit/s. While this is less than the 100 Mbit/s specified for Ethernet, it is sufficient to support the necessary PIS applications (including streaming applications expected in the future).

Savings from PLUS PCN by eliminating Ethernet cables and some of the Ethernet switches

Costs

• Less material costs due to fewer cables, connectors and switches

• Less installation costs when laying the cables and devices in the train

• Less maintenance costs

Space requirements

• Less space required for the data network due to fewer cables, connectors, brackets, etc.

Weight

• Less weight: The weight of a vehicle influences the wear and tear of the infrastructure (rails and switches) and has thus become an important purchasing criterion for rail operators. The maximum weight of components such as PIS systems is specified in tenders. Exceeding this limit is penalized.

for cost-effective data communication for monitoring, protection and automation of the Medium Voltage Grid

Worldwide pressure is increasing on the Distribution Grids with the rapid introduction of Distributed Renewable Energy Resources such as wind/solar farms, and loads such as electric vehicles. Future grids must be kept robust to accommodate new energy flow patterns with a high time dynamic characteristic due to the vast amount of spatially distributed sources with time-varying generation.

This requires smart monitoring, protection and automation (MPA) techniques which have been proven successfully already for the Transmission Grid. However, some MPA applications demand high (Mission- & Time Critical – MTC) communication requirements in terms of latency, reliability, etc. which are today only fulfilled by costly broadband networks e.g. fiber optic.

PLUS SMART GRID enables such a cost-effective communication network by transmitting MTC MPA data over the existing medium voltage grid cables between MPA devices, e.g. in the Secondary Substations.

PLUS Smart Grid integrates in addition a highly accurate external reference time PLUS Time Sync in order to support e.g. synchrophasor applications. GPS is generally not seen as suitable in the Distribution Grid as it is often not possible to install the necessary antenna within all Secondary Substations and there are major concerns with the susceptibility of the GPS signal to attacks and spoofing.

PLUS Smart Grid has been installed and tested in a SS cluster in a distribution grid of Bernische Kraftwerke BKW near Berne.

Mission-and-Time-Critical robustness, determinism, low latency

• Robust real-time transmission between SSs with physical data rates of several Mbps, low packet loss and latency down to the range of 5 ms.

• Bus arbitration based on a deterministic protocol

• Peer-to-peer architecture with no single point-of-failure

• Stateless connections minimize setup and recovery times

• Multiplexing of multiple data services onto a single bus

Further information

• PLUS Smart Grid: Smart Grid Multi-Service Communication Network Pilot

• PLUS Time Sync: Precise Time Synchronization of Phasor Measurement Units with Broadband Power Line Communications

• PLUS Smart Grid: Mission- & Time-Critical Medium Voltage Broadband Power Line Communications for Synchrophasor Applications in the Distribution Grid

2023 plc-tec.ch – plc-tec AG | ALL RIGHTS RESERVED – IMPRESSUM | UMSETZUNG WEBTOTAL.INFO